Personnel who carry out machinery health inspections at industrial plants today generally follow pre-defined inspection routes. This “walking-the-beat” approach has proven to be effective for analysis of vibration and infrared thermography because the information derived from on-the-spot, real-time inspections and data collection is extremely useful. These inspections are also economical in many situations where having permanently installed equipment on each asset would be too costly.

Until now, these pre-defined machinery health inspections have not included route-based oil analysis in order to determine lubricant properties quantitatively. It just was not possible previously to perform this type of analysis at each point along the route within a minute (or two at the most). Now, with the development of certain handheld tools such as the FluidScan Q1100, it is feasible to obtain critical, quantitative oil parameters within a short time right at the sampling point (see Figure 1). As a result, it is possible to envision a route-based oil analysis protocol.

Route-based oil analysis is a big step beyond visual inspections by maintenance personnel as they go through a plant along a pre-determined route to perform greasing or topping-off of lubrication systems.

Figure 1. Route-based oil sampling

Of course, technicians should still observe the machinery visually while walking a route, but on-the-spot oil analysis can be done very quickly with good accuracy and with repeatable results. Walk-around analysis provides immediate feedback and the ability to retest right in the field if needed. In many cases, it is not even necessary to use a sample bottle. Route-based oil analysis adds even greater value because the information provided from a structured database is always correct and consistent. No time is wasted, and no human error is incurred, since the route automatically associates reference information with each designated sample point.

By consistently identifying the correct reference oil and asset sample point with a test, the walk-around infrared spectrometer operator can achieve far better repeatability and accuracy than can typically be achieved in a commercial laboratory. Many commercial labs do not have the ability to consistently identify the exact lubricant and other pertinent information related to each test sample. That information is generally not available in the practice of their business.

Figure 2. Visual observations collected

and assigned to samples on a route

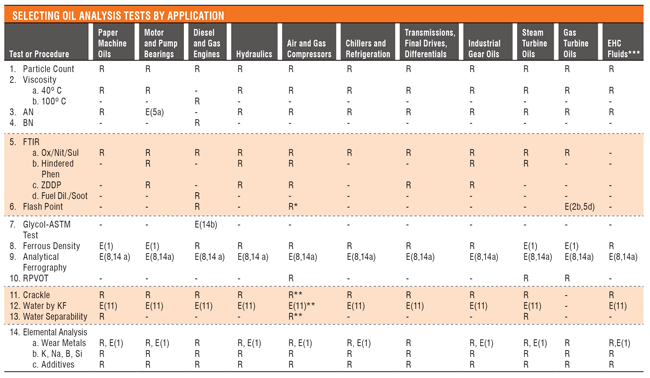

Today’s portable instruments used for route-based oil analysis are able to outperform lab instruments because the information available at the point of the test identifies the appropriate test methods, analysis parameters and alarm limits for each lubricant sample on a sequential route. Simply stated, route-based oil analysis allows technicians to do a better job of oil analysis and get it done quickly because their instruments are programmed to always select the correct protocol and reference information for each point along the route.

Six elements must normally be addressed for a technician to conduct a route-based analysis with a portable analyzer in an industrial plant or around a fleet of mobile equipment:

- Create a structured database.

- Populate the database with route information associated with the oil and equipment in the database.

- Select a preferred inspection route.

- Transfer route information into a handheld analyzer.

- Apply route information in the analyzer during in-field analysis.

- Upload measurements and findings to the database.

Database Creation

A maintenance server is configured to generate oil analysis routes based on a set of analysis rules (see Figure 3). These rules may be based on time, a previously existing condition or specified by the maintenance engineer. The route could include the sequence, asset identification and/or reference oil information, such as oil name, type, property limits, etc.

Figure 3. Creating a route using a structured database

Populating the Database

The generated route is synched between the maintenance server and the device to be used for the route-based analysis. This can be accomplished in a number of ways, including a straight database synch, a file download/transfer or a barcode list, which could serve the dual purpose of a sample bottle label. For a set of recurring routes, a binder could be constructed of 8½-by-11-inch sheets of paper that could be pulled out and scanned whenever a given route is indicated (see Figure 4).

Figure 4. A “route” of points represented by

sequenced machine-readable sample labels

Sample labels afford the benefit of potentially including other data independently collected from the lab or other onsite test instruments into this same sample record. Still another way to accomplish this would be for the user to print and laminate labels and attach them to each sample point. Then, when the technician walks the route, he or she could scan the barcode to add that location to the route in the database.

Route Analysis

With the route information downloaded into the handheld machine, lubricants are analyzed at each asset in sequence. The handheld unit operates in a self-guiding fashion so that the user is presented with the next asset’s information when finished with the analysis of each asset. This may include GPS coordinates of the asset, a picture, serial number or simple instructions on where to find the next asset. The handheld device contains all the calculation tools necessary to perform the analysis.

The results of each lubricant scan are stored in the handheld unit. The technician can see the results as soon as they are produced. This can include alarm limits imported from the maintenance server so that the user can determine immediately if the machine is “in spec” according to the analysis. If the machine is “out of spec,” additional instructions may be offered, such as collect an oil sample at that machine for further analysis.

Transferring Data

When the route is complete, the handheld device is again synched with the maintenance server so the data can be uploaded and the database updated. The maintenance engineer can then review this data and use the server’s analytical tools to determine if any further action is needed.

Planning a System

It is easy to envision how a route-based oil analysis system could be a valuable tool for a large facility where route-based machinery health monitoring is practiced. With the natural flow of data in a route-based system, decision-makers can see how on-the-spot oil analysis could fit into the context of their other asset-management tools. It certainly provides a convenient and practical way to perform oil analysis with minimum or no paperwork. Furthermore, as at-line, in-line and on-line tools are developed for oil analysis as they have been for vibration monitoring, a similar path is envisioned for these two probes of machinery health.

By using route-based oil analysis, users can plan coverage for a whole range of assets based on economic considerations. Dedicated in-line and on-line analyzers that have the same capabilities as the handheld at-line tools may be used where appropriate, with that data stream tied together with the route-based system at the maintenance server and overall system.

It is clear that oil analysis and other probes of machinery health, such as vibration and thermography, have fundamental differences that must be considered when planning how and when to use emerging oil analysis tools. Oil analysis, which is inherently a physical and chemical investigation of the oil including its base, additives, contaminants and wear debris, is significantly different than vibration monitoring or thermography, both of which use information arising directly from the machinery.

When the lubricant within that machinery is analyzed for chemical information, users have another means of assessing the health of the machine, the type and extent of system contamination, and the functional condition of the oil. This extra step needed for oil analysis helps to explain why oil analysis instrumentation is still emerging for on-the-spot, full and quantitative machinery assessment. Nevertheless, significant recent advances in the speed, size and weight of quantitative oil analysis tools indicate a route-based oil analysis paradigm can now be a reality.

Oil-Rite Corp. recently introduced a new line of level gages with adjustable centerlines to accommodate centerline distances up to 1/4 inch longer or shorter than the specified measurement for total adjustability of 1/2 inch. This range of adjustability compensates for variances that can occur during the production of plastic tanks. It is also suited to field installations where the distance between mounting holes may be less precise than in a controlled setting. The adjustment can be made by hand, facilitating simple installation.

Oil-Rite Corp. recently introduced a new line of level gages with adjustable centerlines to accommodate centerline distances up to 1/4 inch longer or shorter than the specified measurement for total adjustability of 1/2 inch. This range of adjustability compensates for variances that can occur during the production of plastic tanks. It is also suited to field installations where the distance between mounting holes may be less precise than in a controlled setting. The adjustment can be made by hand, facilitating simple installation. Panalytical recently introduced upgraded benchtop X-ray fluorescence (XRF) spectrometers incorporating the latest advances in excitation and detection technology. The new Epsilon 3X instruments have been designed for reliable and simple operation while delivering analytical performance across the periodic table.

Panalytical recently introduced upgraded benchtop X-ray fluorescence (XRF) spectrometers incorporating the latest advances in excitation and detection technology. The new Epsilon 3X instruments have been designed for reliable and simple operation while delivering analytical performance across the periodic table.

"What could be the possible reasons for the base number of our gasoline engine oil becoming depleted to 1.2 milligrams of potassium hydroxide per gram (mgKOH/g) after 2,175 miles? The amount of oil was also reduced in the engine when gauged."

"What could be the possible reasons for the base number of our gasoline engine oil becoming depleted to 1.2 milligrams of potassium hydroxide per gram (mgKOH/g) after 2,175 miles? The amount of oil was also reduced in the engine when gauged."

"This winter we sent a sample of a 220-centistoke extreme-pressure gear oil to our lab for routine analysis. The oil was used in an outdoor gearbox for about two years in Canada. Most of the analysis results appear normal (viscosity is 217 centistokes at 40 degrees C, only 100 parts per million water and the acid number is 0.65). However, the flash point is 76 degrees C, which is well below the new oil level of 190 degrees C.

"This winter we sent a sample of a 220-centistoke extreme-pressure gear oil to our lab for routine analysis. The oil was used in an outdoor gearbox for about two years in Canada. Most of the analysis results appear normal (viscosity is 217 centistokes at 40 degrees C, only 100 parts per million water and the acid number is 0.65). However, the flash point is 76 degrees C, which is well below the new oil level of 190 degrees C.  Spectro Scientific recently introduced a new series of instruments for oil analysis, condition monitoring and maintenance and reliability programs.

Spectro Scientific recently introduced a new series of instruments for oil analysis, condition monitoring and maintenance and reliability programs.